AWR Technology - MOTORS

AWR Technology - MOTORSSmall stepper motors supplied with the SYSTEMS 2,4,5. Full torque of 100Ncm is obtained with a gearbox of 125:1 ratio.

Ideas for motor brackets.

Heavy duty gearboxes and larger motors give 200Ncm of torque with 50:1 ratio and upwards for STEP3 motors supplied with SYSTEM5 or FRGEN. The gearbox is also used on MOTOR/G for Microstepping when a large amount of torque is required. The gearbox has all metal gears and is torque limited to 400Ncm.

Ideas for motor brackets.

Large motors which can be connected DIRECTLY to slow motion axes or with small ratio gear reduction to be used in the Microstepping system. The large motor in the picture is MOTOR/400. The telescope reduction ratio needs to be in the range 200:1 to 1200:1

| TYPE | "L" (mm) |

Mounting ctrs (mm) |

Useful torque (Ncm) |

Output shaft (mm) |

Weight (kg) |

Max Phase current (A) |

Notes |

|---|---|---|---|---|---|---|---|

| MOTOR/35 | 48 | 31 | 25 | 5.00 | 0.40 | 1.2 | Needs gears |

| MOTOR/85 | 52 | 47.2 | 60 | 6.35 | 0.7 | 1 | Needs gears |

| MOTOR/210 | 85 | 50 | 130 | 8.00 | 1.3 | 2 | , |

| MOTOR/G | 140 | 56 | 200 | 8.00 | 1.8 | 1.2 | Has 5:1 gearbox |

| MOTOR/400 | 83 | 70 | 300 | 12.00 | 2.6 | 4 | full spec dwg |

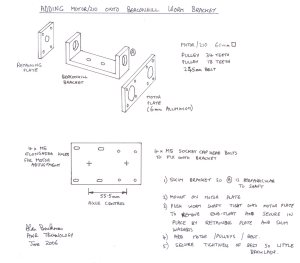

Examples of motor brackets for fixing in various positions. These diagrams were specific solutions for one telescope. It is left to the user to work out how to adapt these for their own telescope. The worm wheel in the DEC examples was supplied by Beacon Hill Telescopes.

The function of the bracket is to hold the motor rigidly in position so that all the torque it develops is transferred to rotating the telescope axis rather than twisting up the metal in the bracket. For this reason the metal of the brackets must be substantial. We use 5mm thick Aluminium material as a minimum.

(Download formats: PDF files are about 250K, JPG are much smaller.)

|

|

| The original worm brackets went through several stages of evolution. We have picked out the SKELETON VERSION which had synchronous motors fitted (in a large can) and the SOLID VERSION which has a shaft both ends. We can drive both of these types. The skeleton version is more involved as it requires a shaft extension, bearing and thrust washer to be added. One concern has been extra weight added as there is one large adjust screw to mesh the worm with the wheel but it is possible to add two extra grub screws to secure this once it has been adjusted. So we are using a smaller motor weighing 0.7kg and pulley drive reduction about 3:1 to give the required huge torque! Look at the drawings of the original brackets and the sketch of how our motor fits on.

|

|

| MICROSTEPPING MOTOR ASSEMBLIES (PRICES PER AXIS) | ||||||

|---|---|---|---|---|---|---|

| MOUNT | MOTOR | MECHANICAL LINKAGE | AVAILABLE TORQUE | OVERALL REDUCTION | MAX SLEW deg/s | PRICE |

| Beacon Hill | MOTOR/210 | 2:1 Pulley set and bracket. Motor folded over worm. PHOTO |

3Nm | 574 or 720 |

0.7 | £220 |

| Beacon Hill | MOTOR/210 | Oldham coupling, IN-LINE motor and bracket. PHOTO |

1.5Nm | 287 or 360 |

2 | £170 |

| Beacon Hill, Heritage upgrades |

MOTOR/210 | 2:1 Pulley set. Motor folded over worm. Sprung assembly into the wormwheel in range 100 to 500 Newtons |

3Nm | 574 to 1200 |

0.5 to 0.7 | £400 |

| Fullerscopes MK IV Pictures:1 2 3 |

MOTOR/85 | 3:1 Pulley set and bracket AWR fitting |

1.8Nm | 974 | 0.6 | £155 |

| VIXEN ATLUX conversion |

MOTOR/85 | Gears, brackets and motor carrier plates AWR fitting. DEC housing mod difficult. |

1.8Nm | 974 | 0.6 | RA £105 DEC £230 |

| EQ5 / GP-DX / GPE | MOTOR/32 | 58/16 Gear set and bracket User fitting |

0.8Nm | 522 | 2 | £100 |

| HEQ5 | MOTOR/32 | 72/12 Gear set and bracket Motors fit outside casing. User fitting |

1.2Nm | 540 | 2 | £220 (complete assy) |

| EQ6 conversion |

MOTOR/32 | 57/12 Gear set and brackets New front panel. User fitting |

1.5Nm | 846 | 1.8 | £102.50 |

| ALTER D6 conversion |

MOTOR/32 | Existing, rearranged gears User fitting |

2.5Nm | 2800 | 0.5 | £60 |

| LX200 conversion |

MOTOR/32 | 58/16 Gear set, bracket New front panel. Strip down at AWR |

0.8Nm | 652 | 2.4 (8 inch) |

£115 |

| ASTRO PROMOTIONS conversion 1 2 3 | MOTOR/32 | 5:1 Gearbox, bracket, OLDHAM COUPLING |

1.2Nm | 1000? | 1.6 | £165 |

© 2000 - 2015 AWR Technology